High-Volume

Bearings

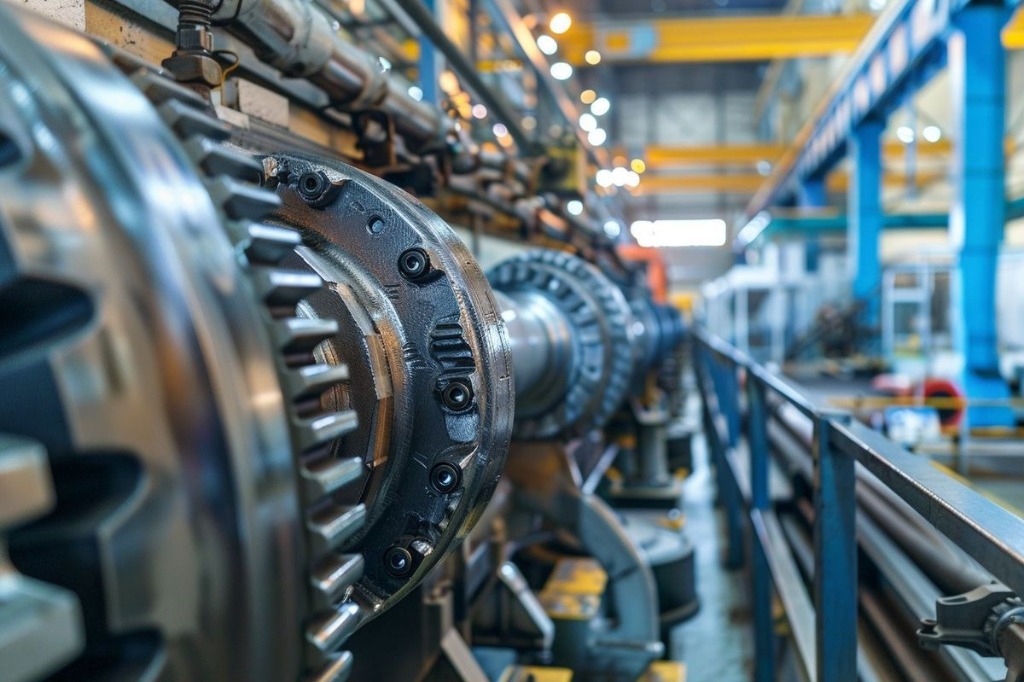

Mastering micron-level accuracy for global production. Our ERP orchestrates complex tolerances, advanced heat treatment, and smart assembly with absolute digital precision.

Precision Tolerance

±0.001μ